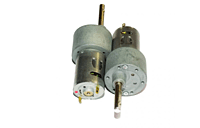

10-Rpm Johnson Motor

A DC motor featuring metal gearbox for driving the shaft of the motor, it is a mechanically commutated electric motor which is powered from DC supply. The Johnson Geared Motors are known for their compact size and massive torque-speed characteristic. They are also used in developing capable robots or robotic platform, various automation purposes.

Non-returnable

Out of stock

Rs.450.00

Share:

Product Details

Key Features:-

Motor Type: The motor is most likely a DC (Direct Current) motor, which means it operates using a DC power supply. DC motors are commonly used for applications that require precise control over speed and direction.

Speed: The motor's speed is rated at 10 RPM, which indicates that it rotates at a relatively slow speed. This makes it suitable for applications that require low-speed and controlled motion.

Voltage: The motor will have a specified voltage rating, such as 12V DC or 24V DC, indicating the voltage at which it is designed to operate. It's crucial to provide the motor with the correct voltage for optimal performance.

Torque: Motors from Johnson Electric typically provide a specified torque rating, which indicates the rotational force they can deliver. The exact torque rating will depend on the specific model and design of the motor.

Applications: The Johnson Geared Motor gives very good torque at an affordable price hence they are widely applicable in Pan/Tilt camera, auto shutter, welding machines, water meter IC card, grill, oven, cleaning machine garbage disposers, household appliances, slot machines, money detector, automatic actuator, coffee machine, towel disposal, lighting coin refund devices, the peristaltic pump and so on. Also, they are best suitable with highly developing capable robots or robotic platform, various automation purposes.

Mounting: These motors are often designed for easy installation and may feature mounting holes, flanges, or brackets to facilitate secure attachment to other mechanical components.

Control: Johnson Motors can be controlled using various methods, including electronic motor controllers, microcontrollers, and switches. The choice of control method depends on the requirements of your specific application.

Direction: The direction of rotation of a DC motor can often be reversed by changing the polarity of the power supply connected to the motor.